The history of Raymond Mill, also known as Raymond Mill, Mill, or High-Pressure Suspension Roller Mill, can be traced back to 1906. At that time, C.V. Grueber founded Curt Von Grueber Machinery Manufacturing Plant in Berlin and produced the first Maxecon mill based on the patent obtained in the United States. This equipment was originally used as coal grinding equipment in the MOABIT power station of BEWAG in Berlin. Subsequently, E.C. Loesche became a shareholder and head of the machinery manufacturing plant, purchased the American patent for the Raymond centrifugal ring roller mill, and produced the first generation of the Raymond mill system. The system is innovative in structure, using a centrally erected rotating spindle with self-rotating grinding rollers suspended on the spindle to grind materials through rotation and centrifugal force.

The first generation of Raymond mills has been widely promoted and applied in areas with softer coal, such as the United States. However, since the coal in Germany is harder and has a high ash content, a higher grinding force is required, so the mill is not popular in Germany. Subsequently, after many improvements, such as the improved Raymond mill developed by E.C. Loesche in 1925, and the VR mill developed by the American Combustion Engineering Company on this basis, the performance and application range of the Raymond mill have been significantly improved.

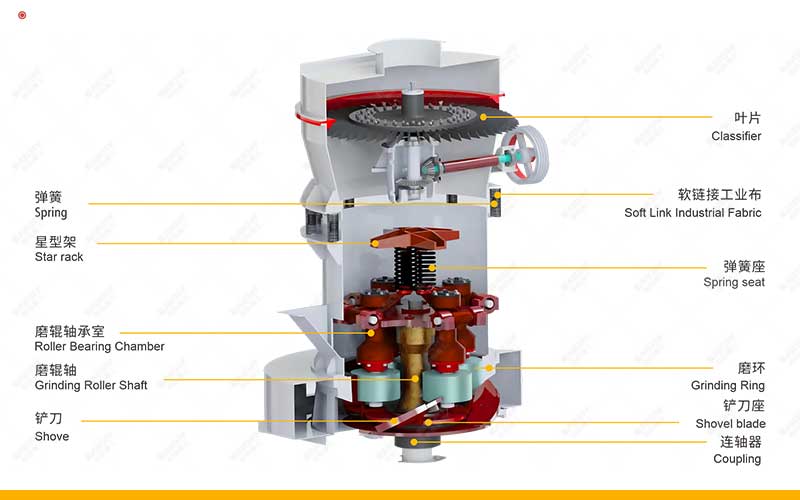

Working principle of Raymond mill

The working principle of Raymond Mill is to add the material to be crushed into the machine from the feed hopper on the side of the machine cover, and rely on the grinding roller device suspended on the plum blossom frame of the main machine to revolve around the vertical axis and rotate. The centrifugal force generated during rotation causes the grinding roller to swing outward and press tightly against the grinding ring. The scraper sends the material between the grinding roller and the grinding ring, and the purpose of crushing the material is achieved through the rolling and rolling of the grinding roller. During the whole process, the airflow system remains closed and circulated, and the balance of airflow is achieved by adjusting the residual air duct between the fan and the main machine, and the excess gas is introduced into the bag filter to ensure the effective collection of dust.

Application of Raymond Mill

Due to its high efficiency, low energy consumption, and low noise, Raymond Mill is widely used in many industries, including but not limited to:

Chemical industry: used for fine grinding of materials such as pigments, coatings, dyes, etc. to improve the color saturation and glossiness of the products.

Pharmaceutical industry: mainly used for grinding and granulation of medicinal materials, improving the solubility and absorption rate of medicinal materials, so that the efficacy of the medicine can be better exerted.

Building materials industry: widely used in grinding production lines of building materials, such as gypsum, lime, dolomite, marble, etc.

Coal industry: Grind coal into fine enough powder to meet the needs of combustion, gasification, and other processes, improve the combustion efficiency of coal powder, and reduce environmental pollution.

Cement industry: Slag can be ground into cement powder to improve its gelling properties.

Food processing: used for fine grinding of ingredients such as grains, beans, and dried fruits, making them easier to process and make food.

Other industries: such as ceramics, glass, electricity, metallurgy, etc., Raymond Mill also plays an important role in these industries.

As an important grinding equipment, Raymond mill has a wide range of applications and important roles in modern industrial production processes. With the continuous advancement of technology and the continuous development of the market, the performance and application scope of Raymond Mill will continue to improve and expand.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing onstone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.